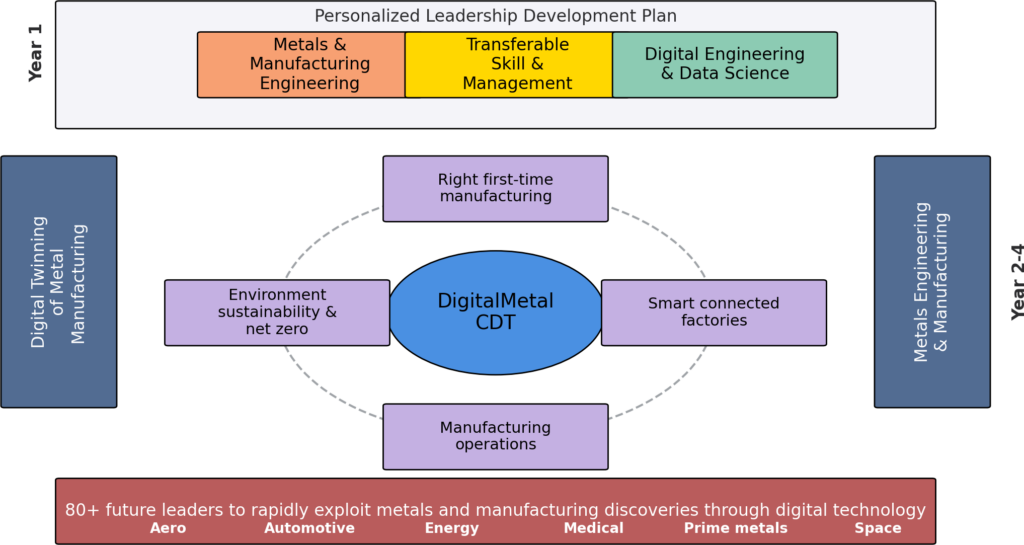

OVERVIEW

The EPSRC Centre for Doctoral Training in Digital Transformation of Metals Industry (DigitalMetal) will train a new generation of eighty leaders ready to transform the metals and manufacturing industry using digital technology; and increasing the industry’s agility, productivity & international competitiveness. All projects are resourced equally, all are industrially supported, and each student receives additional industrial bursaries of £5k per annum on the top of EPSRC standard stipend (subject to projects).

DigitalMetal CDT, led by the University of Leicester, in partnership with Universities of Birmingham, Loughborough, Nottingham, and Warwick, invites applications for about 14 fully funded PhD positions for 2025 entry. This programme is designed to train future leaders equipped with combined expertise in metals and alloy engineering and digital technology and AI, supported by a broad foundation in manufacturing management, product development, leadership, and personal development skills.

Programme Overview

DigitalMetal CDT offer PhD projects in the following 5 research themes in collaboration with world-leading industrial partners, including Rolls-Royce, UKAEA, GKN Aerospace, TWI, MTC, AWE, WMG, Siemens, Qinetiq, Tata Steel, British Steel, HVM Catapult and etc.

DigitalMetal CDT Research Themes:

(1) Advanced manufacturing: Example projects: (i) casting, (ii) welding, (iii) surface engineering, (iv) near net-shape forming, and (v) additive manufacturing, (vi) Intelligent and robotic manufacturing of metals and alloys

(2) Metals and alloys engineering: Example projects: (i) development of Ni-base superalloys, (ii) development of high-performance alloys

(3) Multi-objective digital twinning of manufacturing processes: Example projects: Digital twining of (i) casting, (ii) welding or (iii)additive manufacturing high performance engineering structures for aerospace, energy and medical applications, (iv) digital twinning of steelmaking processes

(4) Digital-enabled right-first-time manufacturing: Example projects: (i) digital manufacturing of lightweight & multi-functional space structures, (ii) right-first-time manufacturing for environmental sustainability and net zero in metal manufacturing

(5) Engineering management and manufacturing supply chain study using digital tools. Example projects: (i) use of Industry 4.0 to enhance decision making, (ii) supply chain co-ordination for sustainability, (iii) use of technology for supply chain visibility

Career Prospects

Graduates of the DigitalMetal CDT will be uniquely prepared to excel in academia, industry, or policy roles. The training programme provides a solid foundation for careers at the forefront of digital transformation in manufacturing, ensuring participants are equipped to lead innovation in one of the UK’s most significant industries.

Autumn 2026 Intake Application is NOW OPEN

Click HERE to apply (Please note all applications must be submitted through the University of Leicester portal)uccessful candidate is allocated.

CDT in DigitalMetal studentships are for 4 years and are funded by EPSRC and provide:

- Tuition fees at UK (Home) rates*

- Annual stipend of £20,780 with an additional £5,000 industrial top-up (subject to projects)

- £4,000 Research training support grant (RTSG)

The DigitalMetal-CDT has the current listed projects open for application. The call is also open for applications for all 5 DigitalMetal research themes.

- Optimisation of Liquid Metal Filtration and Cleanliness in Nickel-Based Superalloys; University of Birmingham + Rolls-Royce

- Development of Advanced Barrier Coatings for Extreme Environments; University of Nottingham + Rolls-Royce

- Evaluation of Stainless Steels and Nickel Alloys for Ammonia Service; University of Leicester + TWI

- Data-Driven Selection Strategies for Directed Energy Deposition Technologies; University of Loughborough + MTC

- Solid-State Additive Manufacturing of Nickel Aluminium Bronze Alloy; University of Nottingham + BAE Systems

Our unique doctoral training model:

This transformative training, moving from traditional PhD models to a π-model that spans multiple domains, prepares a new generation of engineers to address complex challenges and attract global investment, thereby driving UK economic growth and maintaining a competitive edge internationally.